Manufacturers use heat numbers on Mill Test Reports to track raw materials. Manufacturers physically stamp heat numbers on the material, such as pipe, for tracking purposes. Heat numbers work like batch numbers so companies can trace the material back to the manufacturer and the process batch in which it was made. These numbers provide traceability about the quality of the material being used.

Eclipse helps you track these heat numbers on the MTR sheets and ensure that each product requiring an MTR sheet ships with an MTR sheet. In an RF Warehouse, enter these numbers during the picking process to make sure that the material picked is the material that was ordered and the respective MTR sheet can be sent when shipped.

For more about handling MTR sheets, see Mill Test Reports Overviews in Product Maintenance.

Use the Disable Printing MTRs At RF Close control maintenance record to skip printing the MTR documents when the picking process closes.

To add a heat number during RF picking:

Select the order you need to pick requiring heat numbers.

If the sales order has the Print MTR check box selected, the Enter Heat Numbers screen displays automatically with a new sheet number ID.

Note: You can use the <NAME> hot key to display the Enter Heat Numbers screen.

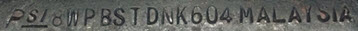

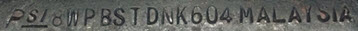

In the Heat Number field, enter the heat number as it displays on the product.

Note: If heat numbers are provided using bar codes, use the RF scanner to scan the bar code instead of entering them manually.

Use the Qty field to indicate how many of that product with that specific heat number you are picking.

You can split order quantities, if needed.

Use the Ht#List hot key to display a current list of heat numbers assigned to the sales order.

Press Esc to save changes and exit the screen.