Eclipse uses four different warehouse schemes:

Warehouse schemes let you decide the most efficient way to purchase and store the products for your company. For example, if you have a small company it may be more cost effective for each branch to purchase and store its own products. However, if you have a large company with many branches, it might be better to have a central warehouse scheme and store all surplus products in one branch and ship only those items that are needed to the branches.

Rules for defining warehouse schemes and an example are provided below.

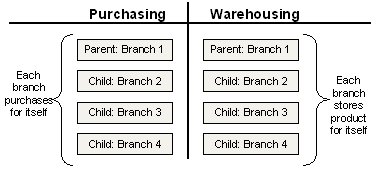

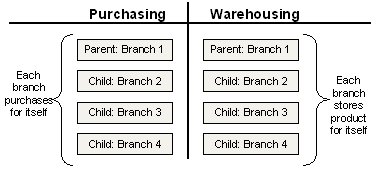

In distributive purchasing a branch does its own purchasing and warehousing. Distributive purchasing is used primarily for single-branch companies. The system generates a Suggested P/O for the branch when that branch needs to replenish its stock.

Distributive purchasing's focus lies in each branch being responsible for its own needs. As illustrated in the following figure, every branch purchases and warehouses the products needed for that branch.

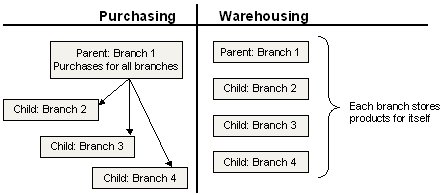

In central purchasing, a parent branch coordinates purchasing for one or more child branches. Central purchasing's strength is that these branches combine their purchasing power to meet a vendor target while allowing inventory to go directly to the branches without transfer replenishment costs. Then, each branch receives and warehouses its own stock, as illustrated in the following figure.

The system determines and uses a common order cycle to generate a Suggested P/O that reflects the combined needs of all partner branches. After generating the Suggested P/O, you convert the suggested purchase order to an actual purchase order for each branch.

In the central purchasing warehouse scheme, the vendor can determine how the child branches are replenished. If the vendor is willing to deliver to each branch individually, you can use Drop Points Maintenance to indicate how those deliveries are made. Then, the ship branch is different for each child branch, and the purchase order is divided into multiple generations by the system. Use the Combine All Branches on a Central PO function from Buy Line Maintenance, through the Information > Additional Data menu option, to separate the generations into individual purchase orders that print for each branch.

If you use Eclipse Forms and you want to configure the form for printing all generations use the Include all generations on this form check box on the Eclipse Forms Maintenance window. When set for a purchase order, the purchase order prints a form that consolidates all generations that use the same drop point.

However, if the vendor is willing to separate each branch's items to individual pallets, but only delivers to the parent branch, then you can use the Cross Dock program at the parent branch to distribute the products among the child branches. This is similar to Central Distribution.

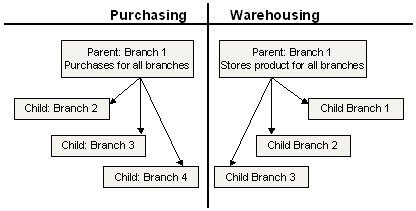

In central warehousing, a parent branch coordinates purchasing and storing products for one or more child branches, as illustrated in the figure below. These branches combine their purchasing power to meet a vendor target.

In this warehouse scheme, a child branch needs to be replenished when the projected inventory level (PIL) of an item drops below the transfer point for the item at the child branch or below the maximum value for the item in the branch if you use Min/Max Values. Use the Suggested Automatic Transfer program or the Cross Dock program to determine which child branches need replenishment of which items. The program uses a series of calculations and conditions to determine the quantity of stock available at a parent branch for replenishment of child branches.

The system determines and uses a common order cycle to generate a Suggested P/O Queue that reflects the combined needs of the parent branch and its child branches. After generating the Suggested P/O Queue, you can convert the suggested purchase order to an actual purchase order for the parent branch.

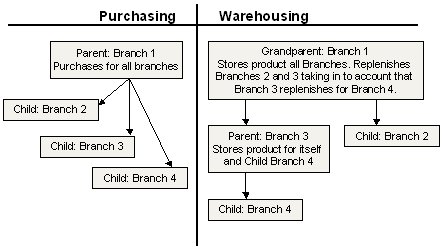

In central distribution, a grandparent branch coordinates purchasing and storing products for one or more parent branches. A parent branch coordinates storing only for one or more child branches. The branches combine their purchasing power to meet a vendor target. The grandparent branch receives and warehouses the stock for other parent branches, which subsequently replenish child branches.

For example, as illustrated in the following figure, Branch 1 purchases and warehouses for all branches. When Branch 1 replenishes Branch 3, it sends enough to meet the needs of both Branch 3 and 4.

The system determines and uses a common order cycle to generate a Suggested P/O that reflects the combined needs of the grandparent branch and all the dependent branches. After generating the Suggested P/O, you can convert the suggested purchase order to an actual purchase order for the grandparent branch. The grandparent branch uses the Suggested Auto Transfer program to replenish the parent branches. The parent branches use the Suggested Auto Transfer program to replenish the child branches.

Following are the rules for defining warehouse schemes for procurement groups:

Every procurement group must have at least one distributive purchasing branch.

This branch can be any branch in the network.

More than one branch (or even all branches) can be defined.

Other branches can use this purely distributive branch as a central warehouse and/or central purchasing warehouse.

If the warehousing branch is not the same as the sales branch, the purchasing branch assigned must match the purchasing branch assigned to the parent warehousing branch.

When setting up parent and child branches, the parent/child branch relationship must begin with a parent that is not a child to another branch, and terminate with a child branch that is not a parent to another branch. Otherwise, the configuration would form an impossible supply loop.

Following is a sample warehouse scheme set up using the above rules:

|

Sls Br |

Whs Br |

Buy Br |

|

|

1 |

1 |

1 |

Branch 1 is a distributive branch; it sells, warehouses and buys for itself. |

|

2 |

2 |

2 |

Branch 2 is a central distribution branch that purchases for Branches 3, 4, and 5. It warehouses for Branch 3, which in turn warehouses for Branches 4 and 5. |

|

3 |

2 |

2 |

|

|

4 |

3 |

2 |

|

|

5 |

3 |

2 |

|

|

6 |

6 |

6 |

Branch 6 does central purchasing for Branch 7, but each branch warehouses its own stock. |

|

7 |

7 |

6 |

|

|

8 |

8 |

8 |

Branch 8 is a central warehousing branch that purchases and warehouses for Branch 9. |

|

9 |

8 |

8 |

See Also: