Establishing a Minimum Order Cycle prevents unnecessary and costly processing of purchase orders.

The order cycle is the normal number of days between your purchasing. The amount of days in an order cycle is based on the order point, plus the lead time, plus the time to get to the vendor target. Each product has its own order cycle.

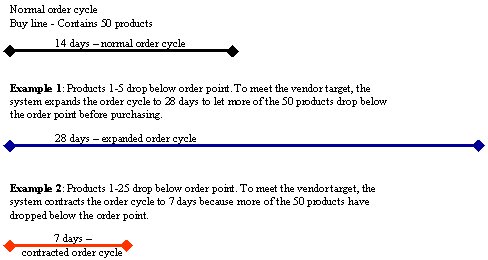

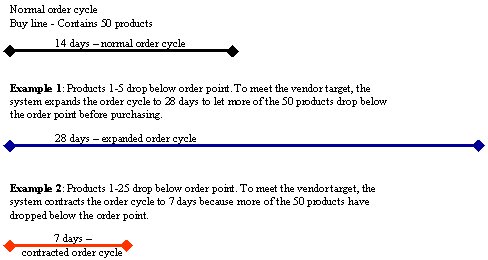

An order cycle can vary because a buy line can contain products that sell both quickly and slowly. The order cycle can expand or contract based on how many products are below the order point of the buy line.

The Suggested P/O program occasionally adjusts the estimated order cycle and line points. This adjustment might be caused by a change in the order, large unshipped stock commitments, increased sales since the last forecasting of demand, or the procurement of non-stock items that contribute to meeting the vendor target but do not have line points.

If only a few products are below their order point, the Suggested P/O expands (adds days to) the order cycle, suggesting you purchase more items to meet the vendor target. The Suggested P/O expands an order cycle to a maximum of 365 days. This maximum prevents you from incurring carrying costs when holding inventory for a long period of time.

If many products are below their order points, the Suggested P/O contracts (subtracts days from) the order cycle, suggesting you need to purchase fewer items to meet the same target. The Suggested P/O never contracts an order cycle below the minimum order cycle defined either at the buy line or the system level. The minimum order cycle is set to keep the system from making suggestions too often. This contraction prevents you from processing unnecessarily frequent purchase orders for a buy line.

For example:

It is possible to exceed the vendor target to meet the minimum order cycle. For example, you make a line buy and two days later go below order point, putting the buy line back in the Suggested P/O Queue. You decide on a reasonable minimum order cycle below which the Suggested P/O program does not contract to meet a vendor target. If the normal order cycle is 209 days and the minimum order cycle is 14 days and there is a run on inventory, this would cause the order cycle to contract to 12 days. The system suggests buying 14 days, even if it exceeds the vendor target.

See Also:

Setting Minimum Order Cycle Days for Buy Lines